The NZ-50 centrifugal separator is suitable for tasks involving low volume flows and solid quantities. Sludge is drained manually. The compact design allows easy integration in production systems, for example on machining centres. Thanks to special materials, use in aggressive media (90° C, pH 1-14) is also possible.

Application: Fine cleaning of coolant lubricant emulsions and oils, surface treatment baths, washing or vibratory grinding fluids, etc.

- fluid-dynamically designed accelerator hub

- direct drive

- peeler tube, backflow head 5 m

- residual liquid drain at standstill

With its large effective rotor diameter, the high-performance 4 kW drive, and thanks to the special inlet hub the separator U-15 achieves a very good separation level of down to 3 µm. The cleaned medium leaves the separator under pressure (5 m pumping head), the sludge is dry and can be removed without residual liquid. Due to the direct drive system the separator is very compact.

Application: all kinds of industrial fluids, typically mechanical processing (coolant lubricant emulsions and oils, washing or vibratory grinding fluids), surface treatment or glass grinding. The separator U-15 is also available in 3-phase version (simultaneous separation of a light secondary liquid phase, e.g. tramp oil)

- auto-priming

- low entry level

- direct drive

- silicon sand filled double casing

- peeler tube, backflow head 5 m

- flow rate up to 150 l/min

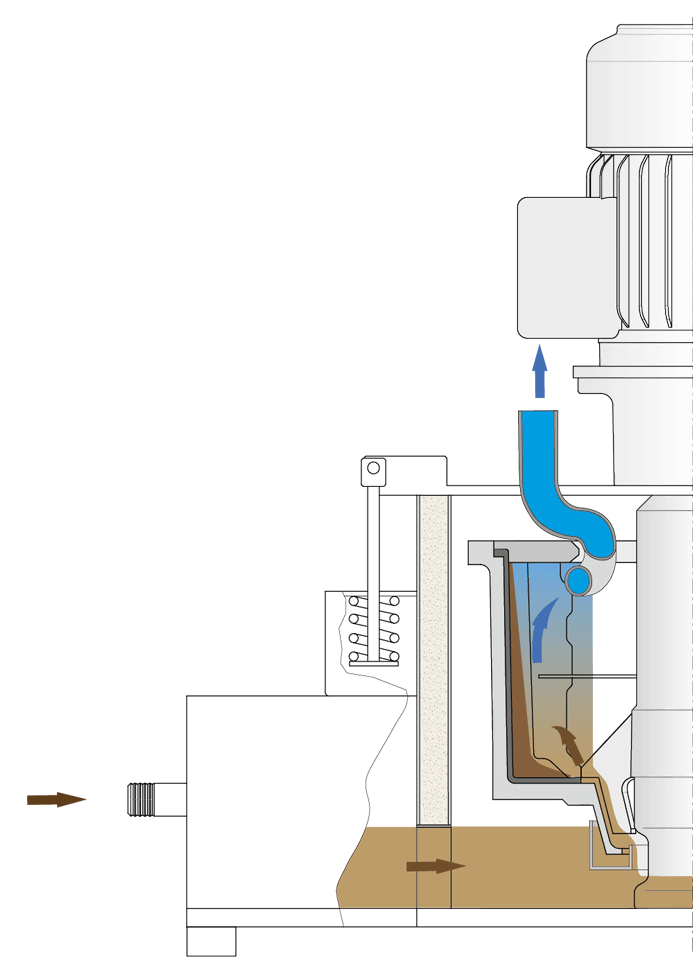

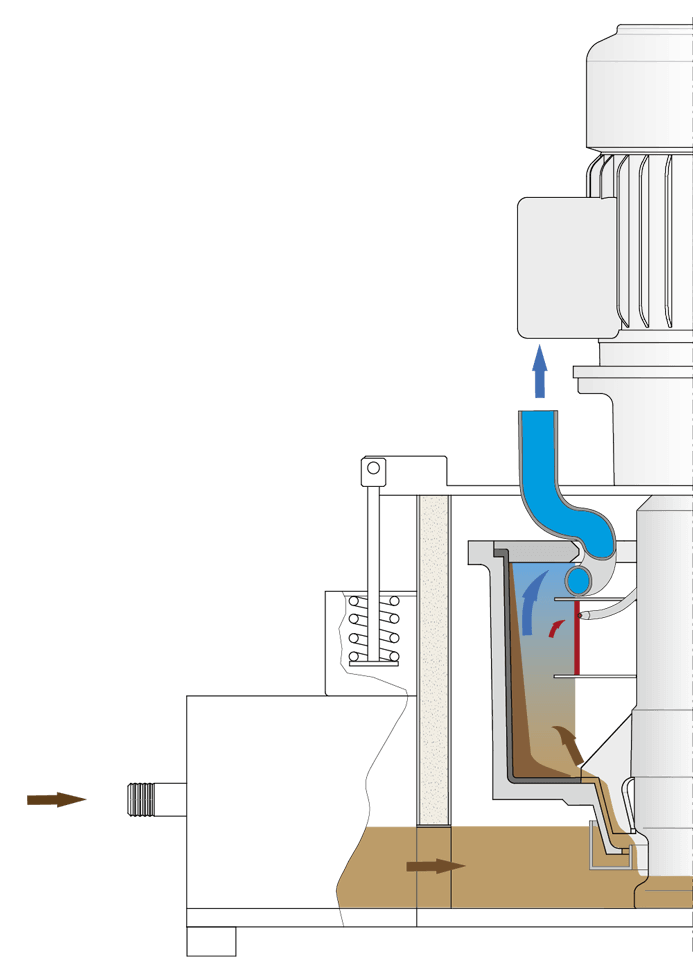

With this model, optimum filter fineness can be achieved – depending on the flow rate, up to 1 µm. Solids are drained manually. Thanks to the robust design (double jacket, direct drive, double mounting), this model is also suitable for use under extreme conditions. The self-priming design principle, in which the fluid is drawn in directly through the lower open drum, provides decisive advantages:

- High separation capacity, as the fluid enters the centrifugal directly, avoiding swirling

- Low sludge residue moisture, as residual fluid flows downwards before draining

- Flexible use, thanks to low inlet height (16 cm) and return of cleaned fluid at approx. 0,5 bar pressure, mobile system

Thanks to special materials, use in aggressive media (90° C, pH 1-14).

Application: Fine cleaning of industrial fluids, usually with receiving volumes of up to 15 m³, for example coolant lubricant emulsions and oils, surface treatment baths, washing or vibratory grinding fluids, etc. The separator S-15 is also available in 3-phase version (simultaneous separation of a light secondary liquid phase, e.g. tramp oil).